Your Familiar Polling Place May Have Closed but You Have Many Voting Options

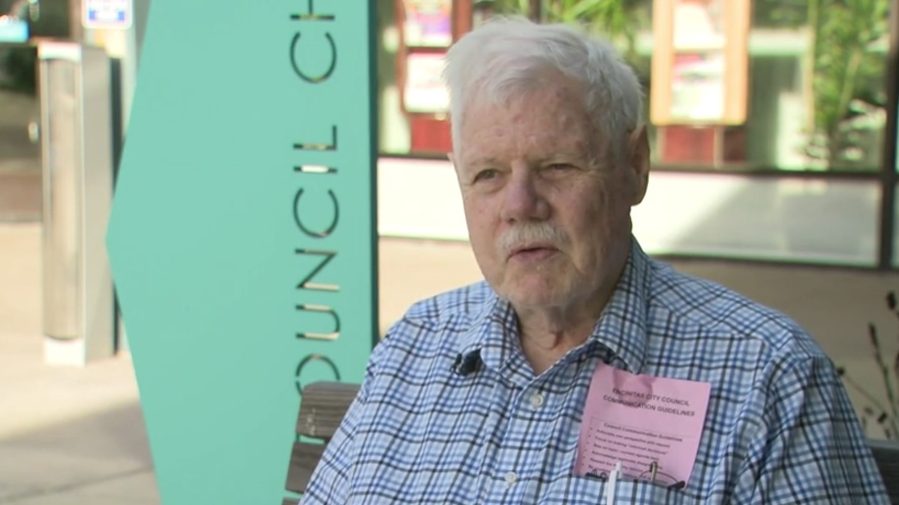

Blue Lake voters planning to cast a ballot in the November election may need revise their voting plans. “For the first time in the almost 50 years that we’ve been voting in Blue Lake, there will be no place to vote in-person in our city,” Lin and David Glen wrote in an email to the Journal. “Today, we talked to our friends about this — all highly engaged, politically aware, committed Blue Lake voters — and not one of them knew that Blue Lake would have no place to vote in-person on Nov. 5. We’re concerned that on Nov. 5, some voters will go to Prasch Hall — last year’s polling place — expecting to vote, but it will be closed. It may be too late for them to make other plans.” Humboldt County Registrar of Voters Juan Paul Cervantes tells the Journal it is true Blue Lake will not have a vote center location this election, saying the Humboldt County Elections Office has been trying to push that message out on social media. He notes the information is also listed on the sample ballots